Street Rodder Road Tour–Custom Trim

With the big stuff out of the way (top chop, body channel, and other body modifications), we could concentrate on some of the smaller details on the car, such as the side trim. In the Eric Black rendering, a thin piece of trim is shown running down the side of the car, with a stylish dip just past the rear wheel opening. To make this happen, we once again called on Richard and Delton, as they are the metal masters of this project. Keep reading to see how they did it!

Richard starts with a flat piece of steel, and makes a few marks to designate the cut lines, and the break lines. He will use the stomp shear to cut the metal.

Once the cuts are to his liking, he double checks his measurements and places the strip of steel into the metal brake. The bends need to be 180-degrees, so brake will get him close, but not all the way to 180.

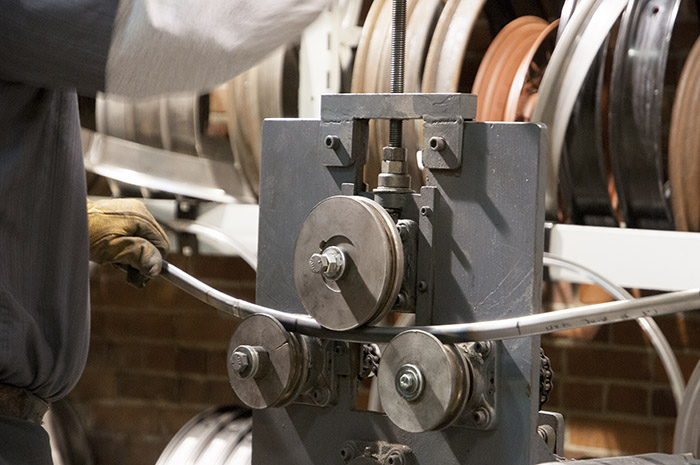

The piece of trim has a natural bow in it so Richard ran it through the bead roller to help straighten it out. This also helps fold the edges flat.

The door and front fender pieces are fairly simple since they are straight. Richard filled the original trim holes, and drilled new ones for the new trim.

The ends of each piece are folded over, trimmed and welded to have a clean look that doesn’t snag when the door is opened.

As for the quarter panel pieces, they were NOT easy! The dip just behind the rear wheel opening offered a big challenge. Delton figured it out though…

Delton took melted lead, left over from the lead bodywork, and melted it into the trim. This gives the trim a strong backbone, so he can make the necessary bends.